These materials can be stretched and bent to a fairly large degree without suffering any deformation. These are used for recording the patient's mouth where undercuts are present. Usually used for partial dentures, over dentures, implants and crown and bridge work .The elastic impression materials are:

Introduction to Elastomers

These are used where a high degree of accuracy is needed, especially in crown and bridge work. They have two main advantages over the Hydrocolloids - good tear resistance and dimensional stability.They are mainly hydrophobic rubber based materials. All of these materials come in different viscosity's ranging from low to high viscosity. The light bodied material maybe used as a wash impression over a medium or heavy-bodied material. There are two ways this can be carried out as described below.

ONE STAGE IMPRESSION

Light bodied impression material is placed in a syringe, and placed over the areas where high detail is required (e.g. over a crown preparation). Some is then squirted over the heavy-bodied impression material which has been loaded into an impression tray. The impression is then taken as normal. This technique saves time, but it can be very labour intensive because the two need to mixed at the same time often requiring more than one DSA.

TWO STAGE IMPRESSION

An impression is taken with the heavy-bodied material. This is then removed from the mouth and inspected. The light bodied material is then prepared and again placed in a syringe. This is then squirted over heavy-bodied material and then impression relocated in its original impression.

Polysulphides

Silicones

Polyethers

Polysulphides

CLINICALLY

Used for crown and bridge work mainly, but also used for partial dentures, overdentures and implants. Two equal lengths are mixed together with a spatula for about a minute. The tray needs to be treated with an adhesive (rubber solution in acetone) to provide retention for the polysulphide. Taking the impression is delayed by 5 minutes before the impression is placed in the patients mouth - the final setting time is usually about 10 minutes from the start of mixing - this delay therefore decreases the amount of time the impression tray is in the patients mouth. A one or two stage impression technique may be used. Although dimensionally stable, the impression should be cast within 24 hours.

CHEMISTRY

Other names : Thiokol rubbers, rubber base or mercaptan.

Supplied as two pastes mixed in a 1:1 ratio.

BASE PASTE

· Polysulphide (forms rubber on polymerisation)

· Filler (to give body)

· Plasticiser (control viscosity)

ACTIVATOR PASTE

· Inert oil (forms a paste)

· Sulphur (facilitates the reaction)

· Lead oxide (causes polymerisation and cross-linking)

The active constituent in the base paste is the polysulphide and the active constituents in the activator paste is lead oxide and sulphur which cause further polymerisation of the polysulphide.

On mixing crosslinking and chain lengthening causes the material to become an elastic solid after about 5-8 minutes. Setting is more rapid in the presence of moisture.

They come in three types: light, regular and heavy bodied (viscosity increasing from light through to heavy bodied). The light bodied polysulphides are used as wash impressions on heavier bodied impression materials. The medium and heavy-bodied impression materials may be used on their own.

PROPERTIES

- Dimensional stability

- Excellent surface detail (is only used in special trays)

- Viscosity depends on the brand used

- Very small setting contraction (0.3-0.4% over the first 24 hrs)

- Contraction on cooling from mouth to room temperature

- Very good tear resistance

- Good shelf life

- Viscoelastic

ADVANTAGES

- Dimensional stability

- Accuracy

- Comes in a number of different viscosity's

- Long working time (although this may be a disadvantage in some clinical situations)

- Long shelf life

DISADVANTAGES

- Lead oxide in base paste may have toxic effects

- Staining of clothes due to the Lead oxide

- Messy to work with - unpleasant rubbery smell

- Can only be used in a special traY

Silicones

The silicone impression materials are classified according to the type of chemical reaction by which they set.

Addition

Condensation

Addition silicones

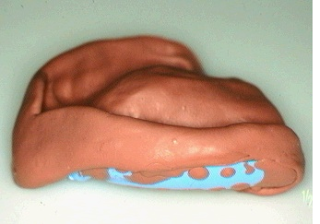

Can be used as a one or two stage technique. May be used in special or stock trays. The very heavy bodied materials are measured in scoops and are mixed by hand until homogeneous in colour.

| 1) An example of an addition silicone - Xantropen | 2) An example of an addition silicone - Kerr's Extrude |

Properties of Addition Silicones

CHEMISTRY

These materials are often termed vinyl polysiloxanes.

Supplied in 2 pastes or in a gun and cartridge form as light, medium, heavy and very heavy bodied.

One paste contains a polydimethylsiloxane polymer in which some methyl groups are replaced by hydrogen. The other paste contains a pre-polymer in which some methyl groups are replaced by vinyl groups, this paste also contains a Chloroplatinic acid catalyst.

On mixing, in equal proportions, crosslinking occurs to form a silicone rubber. Setting occurs in about 6-8 minutes.

PROPERTIES

- Good shelf life

- Dimensionally stable

- Moderate tear strength

- Excellent surface detail

- No gas evolution

- Non toxic and non irritant

ADVANTAGES

- Accurate

- Ease of use

- Fast setting

- Wide range of viscosity's

DISADVANTAGES

- Hard to mix

- Sometimes difficult to remove the impression from the mouth

- Too accurate in some circumstances (cast produced is not sufficiently oversized)

Condensation Silicones

CLINICALLY

Used for crown and bridge work mainly, but also for partial dentures, implants and overdentures. Used in stock trays or special trays. One or two stage impression stage. Although dimensionally stable the impression should be cast within 24 hours.

CHEMISTRY

Supplied as a paste and liquid or two pastes, in light, medium, heavy or very heavy bodied (putty).

BASE PASTE

- Silicone polymer with terminal hydroxy groups

- Filler

CATALYST PASTE

- Crosslinking agent (organohydrogen siloxane)

- Activator (dibutyl-tin dilaurate)

On mixing the two pastes react, cross linking occurs and setting takes about 7 minutes.

The setting reaction is a condensation reaction.

Hydrogen gas is evolved on setting which leads to surface pitting, and a roughened surface to the resulting model.

PROPERTIES

- Hydrophobic

- Hydrogen gas evolution on setting

- Moderate shelf life

- Moderate tear strength

- Good surface detail

- Shrinking of impression over time

- Non toxic and non irritant

- Very elastic (near ideal)

ADVANTAGES

- Accurate

- Ease of use

- Can be used on severe undercuts

DISADVANTAGES

- Hydrogen evolution

- Liquid component of paste/liquid system may cause irritation

Polyethers

Used for crown and bridge work, partial dentures, implants and overdentures. Mixed in a 1:1 ratio until homogeneous colour, the amount of catalyst used can be used to control the setting time. Used in special or stock trays with an adhesive. A one or two stage technique can be used. Although dimensionally stable the impression should be cast within 24 hours.

Properties of Polyethers

CHEMISTRY

Based on imine chemistry

Supplied in two pastes

BASE PASTE

· Polyether

· Filler

CATALYST PASTE

· Sulphonic acid ester (enhances further polymerisation and crosslinking)

· Inert oils

When mixed the polymer and sulphonic acid ester react to form a stiff polether rubber.

Setting time occurs in about 6 minutes.

Usually only comes in one viscosity - regular bodied, but can also come as light + heavy bodied (Diulent)

Heat and moisture speed up the setting reaction.

PROPERTIES

- Hydrophillic (ie absorbs water)

- Good shelf life of up to 2 years

- Good elastic recovery

- Non toxic

- Low setting contraction

- Low tear strength

- Excellent surface detail

- Good dimensional stability

ADVANTAGES

- Accuracy

- Good on undercuts

- Ease of use

DISADVANTAGES

- May cause allergic reaction due to the sulphonic acid ester

- Poor tear strength

- Rapid setting time (ie short working time)

- Stiff set material (sometimes hard to remove from mouth)